OUR SERVICES The company's production programme

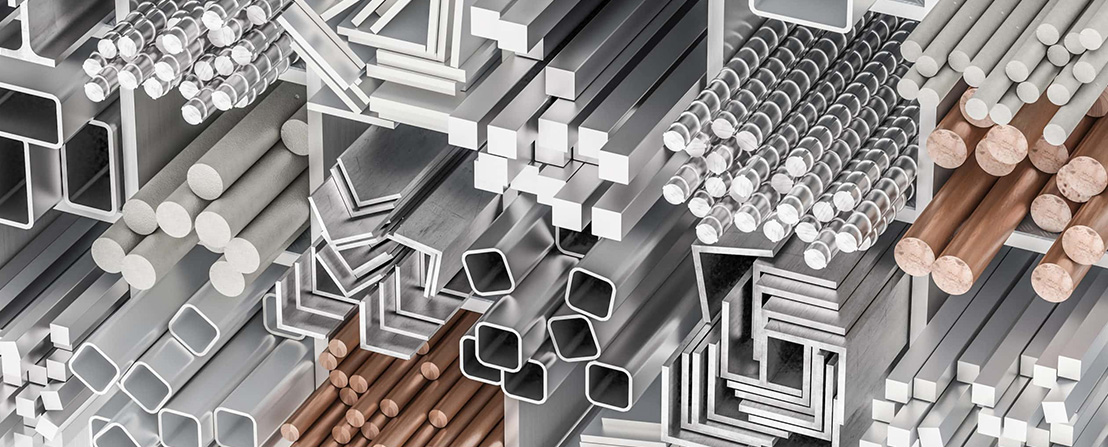

MATERIAL PREPARATION

For material cutting we use BEHRINGER and KASTO band saws, which cut the material

up to a diameter of 360 mm.

To increase the capacity of the material preparation room, we purchased a KASTO Speed C15 circular saw, which will be installed at the beginning of next year.

KASTO speed c15

Machine Description:

Circular saw for steel KASTOspeed C15

Cutting range: 20-153 mm

Cutting speed: 20-160 m/min

Saw blade diameter: 360/425/460 mm

BEHRINGER HBP 360 a

Machine Description:

Behringer HBP 360 A band saw

Cutting range: 10-360 mm

Cutting length: 5-600 mm

Cutting speed: 20-140 m/minS

Saw blade dimensions: 4640 x 34 x 1.1 mm

Behringer hbp 263 a

Machine Description:

Behringer HBP 263 A band saw for metal

Cutting range: 10-260 mm

Cutting length: 5-500 mm

Cutting speed: 14-125 m/min

Saw blade dimensions: 4640 x 34 x 1.1 mm

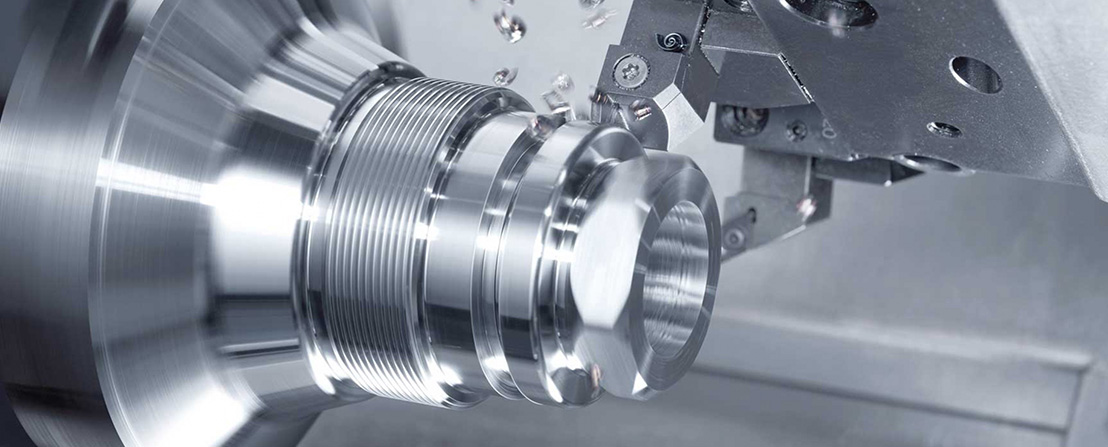

TURNING & MILLING

Our strengths include precision CNC machining. We machine both individual pieces and serial products on top of the range machines from Brother, Hermle, Mazak, Okuma and Tornos,

that excel in precision, reliability and speed of production.

SETTING:

CNC lathes with counter spindles and large Y travel for complex part production

with diameters up to 280 mm and lengths up to 500 mm.

We use modern tooling technologies to enable productive machining.

MILLING:

We own CNC machining centres in 3-axis, 4-axis and 5-axis configurations with the possibility of machining up to 1000 mm length, 600 mm diameter and 500 kg semi-finished product weight. Thanks to the use of CAD/CAM solutions, we are able to produce complex parts using 3D machining. Tool management and accurate tool sizing on the Zoller tool setting machine is a matter of course.

OKUMA LT3000

Machine Description:

Turning centre with two spindles and two turret heads, both with Y axis. Thanks to simultaneous machining on both spindles in conjunction with the robotic workstation, this machine achieves high productivity.

Technical parameters:

Engine power 30 kW

Maximum machined diameter 300 mm

Robotic part loading and unloading

Hermle C42

Machine Description:

The Hermle C42 5-axis machining centre, configured with a stiffer table design, additional tool magazine and Zero Clamp clamping system, achieves high machining efficiency.

Technical parameters:

Engine power 42 kW

Table diameter 800 mm

Table load 850 kg

Brother R650

Machine Description:

High-speed milling, drilling and tapping centre with double-pallet exchanger in a 5-axis design for productive machining with high precision.

Technical parameters:

Engine power 12,8 kW

Spindle speed 10.000 rpm

Table load 200 kg

Tornos Sigma 20

Machine Description:

Tornos Deco Sigma 20 multi-spindle automatic lathe with 3m material feeder. The machine from the traditional Swiss manufacturer of long stroke automatic machines offers high productivity for machining small parts in high volume production.

Technical parameters:

Engine power 5,5 kW

Maximum machined diameter 25,4 mm

Maximum material length 3m

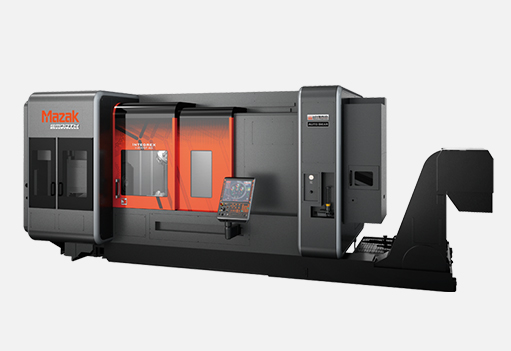

MAZAK INTEGREX I 200 AG

Machine Description:

The Mazak Integrex i 200 multifunctional machining centre in AG version achieves a repeat accuracy of 0.001 mm, enabling the production of gears using the Power Skiving method. In conjunction with the ROBOJOB-TURM robotic tower, this workstation offers productive machining of high-precision parts.

Technical parameters:

Engine power 22 kW

Spindle speed 12,000 rpm

Maximum workpiece weight 30 kg

CONVENTIONAL MACHINING

Our production also includes conventional machines, on which we mainly perform finishing work, the production of various technological preparations, and small series orders.

MACHINING OF CASTINGS

We provide our customers with our long-standing know-how in the field of the finishing and machining of castings and supply them with fully machined products ready for assembly.

MECHANICAL WORK

We assemble not only our own manufactured parts, but also customer parts. Entrust us with your assembly and we will take care of it with the highest quality requirements while meeting deadlines.

Our major customers include